Greenhouse gas emission reduction effect of a straw briquette central heating system

-

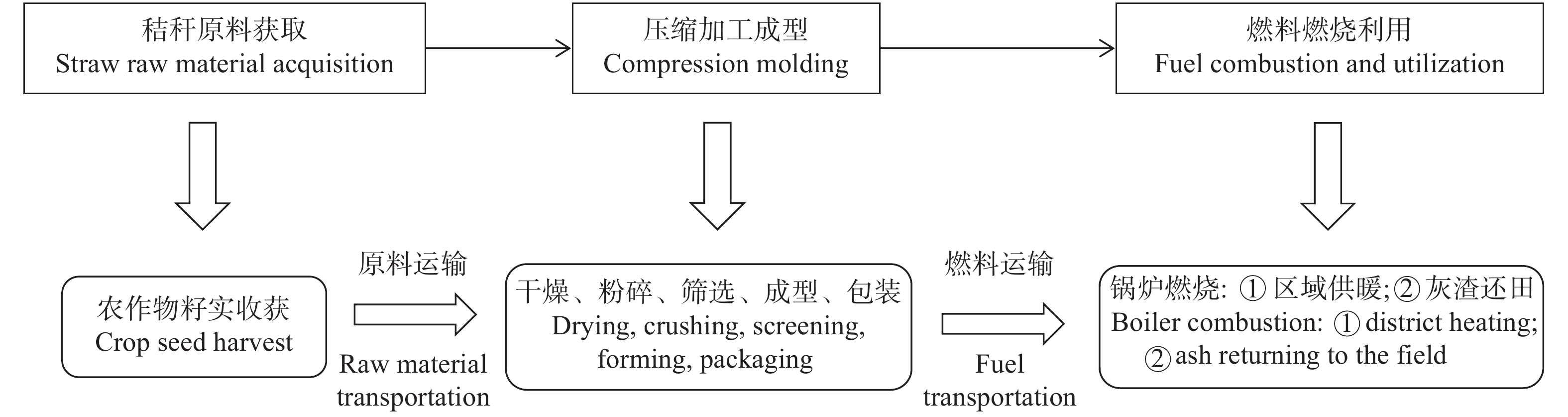

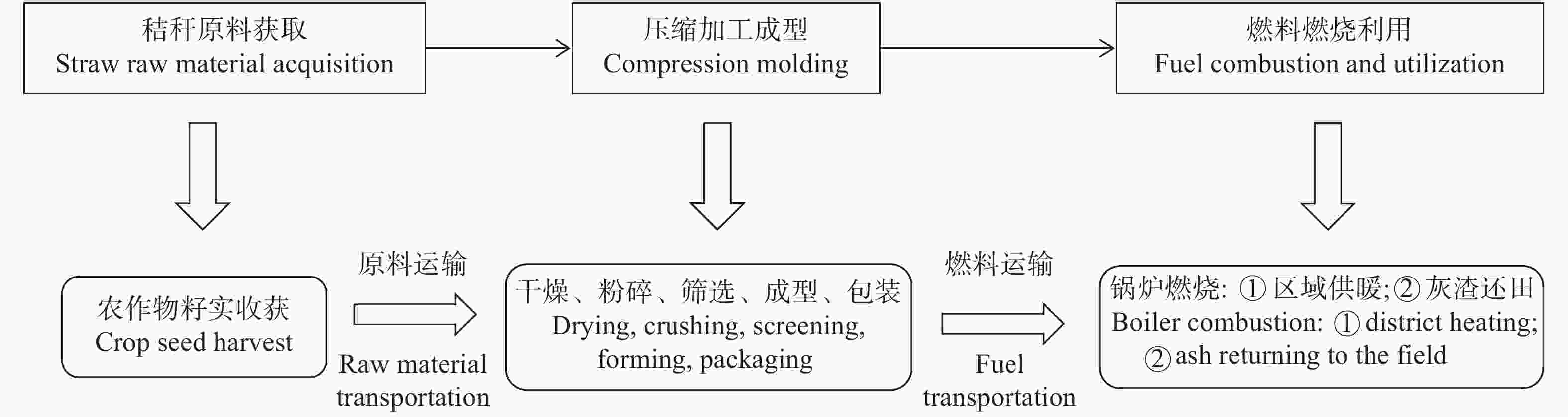

摘要: 探究我国秸秆成型燃料集中供暖工程温室气体减排量计算方法, 定量估算典型工程温室气体减排量, 可为我国秸秆成型燃料集中供暖工程减排量估算提供理论依据与方法支撑。参考IPCC(政府间气候变化专门委员会)《国家温室气体清单指南》、UNFCCC(《联合国气候变化框架公约》)方法学、CDM (清洁发展机制)方法学, 以秸秆自然腐解为基准线, 建立了秸秆成型燃料集中供暖工程温室气体减排量计量方法。该计量方法包括项目边界、基准线排放、项目排放等方面。结果表明, 2019—2020年一个供暖季甘肃省临洮县5个秸秆成型燃料集中供暖示范工程基准线排放量为1610.08 t CO2, 项目排放量为104.67 t CO2, 净减排量为1505.41 t CO2, 约相当于减少了529.45 t标准煤的CO2排放量。临洮县秸秆成型燃料集中供暖工程每消耗1 t玉米秸秆原料, 可减少1.17 t CO2排放。本研究系统构建了基于秸秆自然腐解基准线的秸秆成型燃料集中供暖温室气体减排量计量方法, 完善了秸秆成型燃料集中供暖工程温室气体减排估算方法学体系, 证明了秸秆成型燃料集中供暖工程具有明显的减排效果。Abstract: The long-term dependence on coal for heating during winter in northern China has caused serious environmental pollution. In addition, the limitations and non-renewability of fossil fuels have prompted the development of new energy sources for clean heating. Biomass energy resources are a good option because they are abundant, clean, and sustainable. Crop straw is an important agricultural biomass energy resource in China because of its’ high yield, wide distribution, and variety. Extruding straw into briquette fuel can significantly improve its combustion performance. Referring to the Intergovernmental Panel on Climate Change (IPCC), the United Nations Framework Convention on Climate Change (UNFCCC), and the Clean Development Mechanism (CDM) methodology, and through literature research and field surveys, this study constructed a calculation method for greenhouse gas emission reduction in a straw briquette fuel central heating system, with the natural decomposition of straw as the baseline. The calculation method involves four parts: the system boundary, baseline emissions, project emissions, and leakage. The system boundary includes the disposal of waste straw in the absence of the system, the route of transporting waste straw to the straw molding processing plant, the briquetting machine used in the molding process, the boiler used in the central heating process, the route to transport the straw briquette to the heating point, and the place where the straw briquette is used for heating. Baseline emissions are the sum of greenhouse gas emissions from the natural decomposition of straw, emissions from alternative coal heating, and energy consumption emissions from chemical fertilizer production replaced by returning ash generated by straw to the field. Total emissions of the system are the sum of fossil fuel consumption emissions from engineering transportation activities, power consumption emissions from straw molding, and emissions from utilizing straw molding fuel combustion and heating. The system leakage rate is zero. Finally, the total calculation formula is as follows: net greenhouse gas emission reduction of straw briquette fuel central heating system = baseline emission − energy consumption emission in straw utilization process − project leakage. Using the above methods, a case study was conducted on a straw briquette central heating project in Lintao County, Gansu Province, China. The results showed that in the heating season from 2019 to 2020, the baseline emission of the Lintao straw briquette central heating project was 1610.08 t CO2, the project emission was 104.67 t CO2, and the net emission reduction was 1505.41 t CO2, which is equivalent to reducing the CO2 emission of 529.45 t of standard coal. For every 1 t of corn straw raw material consumed by the Lintao straw briquette central heating system, the CO2 emissions are reduced by 1.17 t. Therefore, it can be concluded that the straw briquette central heating system has an obvious emission reduction effect. This study established a quantitative calculation method for greenhouse gas emission reduction for a straw-briquette-based central heating system based on the background of natural straw decomposition, which enriches the estimation methodology for greenhouse gas emission reduction evaluations. This quantitative study demonstrated that large-scale straw briquette-based central heating projects have a significant emission reduction effect.

-

表 1 秸秆成型燃料集中供暖工程项目边界内主要温室气体排放源

Table 1. Major greenhouse gas emission sources within the straw briquette central heating project boundary

情景

Scene排放源

Source of emission温室气体

Greenhouse gas计入/排除

Included / excluded基准线 Baseline 秸秆自然腐解 Natural decomposition of straw CO2 排除 Excluded CH4 计入 Included N2O 计入 Included 替代化石燃料供暖 Replace fossil fuels for heating CO2 计入 Included CH4 计入 Included N2O 计入 Included 钾肥生产 Potash fertilizer CO2 计入 Included CH4 计入 Included N2O 计入 Included 项目排放 Project emission 将秸秆原料运输到项目现场点的化石燃料消耗

Fossil fuel consumption for transporting straw raw materials to the project siteCO2 计入 Included CH4 计入 Included N2O 计入 Included 秸秆固化成型加工过程(电力消耗)

Straw solidification molding process (electricity consuming)CO2 计入 Included CH4 计入 Included N2O 计入 Included 秸秆成型燃料燃烧供暖 Straw briquette combustion heating CO2 排除 Excluded CH4 计入 Included N2O 计入 Included 表中“排除”原因是: 秸秆成型燃料无论以何种方式利用, 其产生的CO2都不会引起碳库的变化。The reason of “Excluded” in table is that the CO2 produced by straw briquette will not cause the change of carbon pool, no matter how straw briquette is used. 表 2 甘肃省临洮县5个秸秆成型燃料集中供暖试点具体情况

Table 2. Specific situation of five straw briquette fuel based central heating pilot projects in Lintao County, Gansu Province

地点

Location锅炉容量

Boiler capacity

(MW)玉米秸秆成型燃料

消耗量

Fuel consumption of corn

straw briquette (t)原料从收集点运输至供暖点的总距离

Total distance of raw materials transported from

collection site to heating site (km)供暖时间

(月-日)

Heating period

(month-day)供暖面积

Heating area

(m2)八里铺镇政府办公楼

Government building of Balipu Town0.56 140 11 11-01—03-30 2600 新添镇政府办公楼

Government building of Xintian Town0.84 360 17 11-01—03-30 7000 峡口镇政府办公楼

Government building of Xiakou Town0.7 260 40 10-15—04-10 4800 漫湾乡政府办公楼

Government building of Manwan Town0.56 190 65 10-07—04-20 3700 康家集乡政府办公楼

Government building of Kangjiaji Town0.56 180 40 10-20—04-10 3600 合计

Total/ 1130 / / 21 700 表 3 秸秆成型燃料集中供暖工程温室气体减排量估算涉及参数及说明

Table 3. Parameters and description of greenhouse gas emission reduction of straw briquette fuel central heating project

编号

No.参数

Parameter参数描述

Description单位

Unit数据来源

Data source参数取值

Parameter value1 $ {\mathrm{E}\mathrm{F}}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w}} $ 秸秆自然腐解的温室气体排放系数

Greenhouse gas emission factor of

natural decomposition of strawt∙t−1 [17] 4.25×10−2 2 $ {W}_{\mathrm{R}} $ 秸秆含水率

Moisture content of straw% 根据具体项目确定

Determined according to specific project30% 3 $ {N}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w}} $ 工程所消耗的秸秆原料量

Straw raw materials consumed by the projectt 根据具体项目确定

Determined according to specific project1291 4 $ \mathrm{G}\mathrm{W}{\mathrm{P}}_{\mathrm{C}{\mathrm{H}}_{4}} $ CH4的全球增温潜势值

Global warming potential of CH4t∙t−1 [14] 28 5 $ \mathrm{G}\mathrm{W}{\mathrm{P}}_{{\mathrm{N}}_{2}\mathrm{O}} $ N2O的全球增温潜势值

Global warming potential of N2Ot∙t−1 [14] 265 6 $ {\mathrm{E}\mathrm{F}}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w},\mathrm{C}{\mathrm{H}}_{4}} $ 秸秆自然腐解CH4排放因子

CH4 emission factor of straw natural decompositiont∙t−1 [17] 2.32×10−4 7 $ {\mathrm{E}\mathrm{F}}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w},{\mathrm{N}}_{2}\mathrm{O}} $ 秸秆自然腐解N2O排放因子

N2O emission factor of straw natural decompositiont∙t−1 [17] 1.36×10−4 8 $ \mathrm{H}\mathrm{G} $ 因工程实施而消耗的秸秆成型燃料产生的供热量

Heat supply generated by straw briquette fuel consumed

due to project implementationGJ 根据具体项目确定

Determined according to specific project1.93×104 9 $ {\mathrm{E}\mathrm{F}}_{\mathrm{f}\mathrm{o}\mathrm{s}\mathrm{s}\mathrm{i}\mathrm{l}} $ 替代的煤炭的CO2当量排放因子

CO2 equivalent emission factor of alternative coalt∙GJ−1 [18] 0.0970 10 $ {\eta }_{\mathrm{f}\mathrm{o}\mathrm{s}\mathrm{s}\mathrm{i}\mathrm{l}} $ 燃煤锅炉的平均净供热效率

Average net heating efficiency of coal-fired boilers% 根据具体项目确定

Determined according to specific project72% 11 $ {\mathrm{F}\mathrm{B}}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w}} $ 工程所消耗的成型燃料数量

Quantity of straw briquette fuel consumed by the projectt 根据具体项目确定

Determined according to specific project1130 12 $ {\mathrm{N}\mathrm{C}\mathrm{V}}_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w}} $ 秸秆成型燃料的净热值

Net calorific value of straw briquette fuelGJ∙t−1 根据具体项目确定

Determined according to specific project13.746 13 $ {\eta }_{\mathrm{s}\mathrm{t}\mathrm{r}\mathrm{a}\mathrm{w}} $ 燃烧秸秆成型燃料的锅炉的平均净供热效率

Average net heating efficiency of boilers burning

straw briquette fuel% 根据具体项目确定

Determined according to specific project75% 14 $ \mathrm{F}{\mathrm{B}}_{\mathrm{K}} $ 灰渣中钾肥(K2O)总质量

Total mass of potash fertilizer (K2O) in asht 根据具体项目确定

Determined according to specific project4.57 15 $ \mathrm{E}{\mathrm{F}}_{\mathrm{K},\mathrm{C}{\mathrm{O}}_{2}} $ 替代的钾肥生产耗能的CO2当量排放因子

CO2 equivalent emission factor of energy consumption in

alternative potassium fertilizer productiont∙t−1 [19] 0.4094 16 $ {\mathrm{A}\mathrm{T}}_{1} $ 将秸秆原料从田间运输至成型加工点的

农用运输车平均载荷

Average load of agricultural vehicles transporting straw raw

materials from the field to the briquette processing sitet [20] 2 17 $ {\mathrm{E}\mathrm{F}}_{\mathrm{t}\mathrm{r},1} $ 运输秸秆原料的农用车辆的CO2当量排放因子

CO2 equivalent emission factors of agricultural vehicles

transporting straw raw materialst∙km−1 [21-22] 0.2415 18 $ {\mathrm{A}\mathrm{T}}_{2} $ 将成型燃料从加工点运输至供暖点的

中重型货车平均载荷

Average load of medium and heavy trucks transporting straw

briquette fuel from processing site to the heating sitet [20] 5 19 $ {\mathrm{E}\mathrm{F}}_{\mathrm{t}\mathrm{r},2} $ 运输成型燃料的中重型货车的CO2当量排放因子

CO2 equivalent emission factor of medium and heavy trucks

transporting formed fuelt∙km−1 [21] 0.6082 20 $ {N}_{\mathrm{e}} $ 工程运行消耗的电量总量

Total electricity consuming for project operationMWh 根据具体项目确定

Determined according to specific project67.8 21 $ {\mathrm{E}\mathrm{F}}_{\mathrm{e},\mathrm{CO}_2} $ 项目运行所在区域电网的CO2排放因子

CO2 emission factor of the power grid in the area where the project operatest∙MWh−1 《2016年中国区域电网基准线排放因子》

《Baseline Emission Factors of China’s Regional Power Grid in 2016》0.9316 22 $ {\mathrm{E}\mathrm{F}}_{\mathrm{B}\mathrm{F}} $ 燃烧秸秆成型燃料的CO2当量排放因子

CO2 equivalent emission factor of burning straw briquettet∙t−1 [18] 0.027 87 23 $ {\mathrm{E}\mathrm{F}}_{\mathrm{B}\mathrm{F},\mathrm{C}{\mathrm{H}}_{4}} $ 燃烧秸秆成型燃料的CH4排放因子

CH4 emission factor of straw briquette fuel combustiont∙t−1 [18] 6.41×10−4 24 $ {\mathrm{E}\mathrm{F}}_{\mathrm{B}\mathrm{F},{\mathrm{N}}_{2}\mathrm{O}} $ 燃烧秸秆成型燃料的N2O排放因子

N2O emission factor of straw briquette fuel combustiont∙t−1 [18] 3.74×10−5 表 4 甘肃临洮县5个秸秆成型燃料集中供暖试点基准线温室气体排放量汇总

Table 4. Summary of baseline greenhouse gas emissions of 5 straw briquette fuel central heating pilot projects in Lintao County, Gansu Province

排放源

Source of emission八里铺镇政府办公楼

Government building of Balipu Town新添镇政府办公楼

Government building

of Xintian Town峡口镇政府办公楼

Government building

of Xiakou Town漫湾乡政府办公楼

Government building

of Manwan Town康家集乡政府办公楼

Government building

of Kangjiaji Town合计

Total自然腐解排放量

Emission of natural decomposition

[t(CO2)]4.76 12.25 8.85 6.47 6.13 38.45 替代煤炭数量

Quantity of replaced coal (t)68.40 175.88 127.03 92.83 87.94 552.08 替代煤炭排放量

Emission of replaced coal [t(CO2)]194.48 500.10 361.18 263.94 250.05 1569.76 替代钾肥数量

Quantity of replacing potash fertilizer

[t(K2O)]0.57 1.46 1.05 0.77 0.73 4.57 替代钾肥排放量

Emission of replacing potash fertilizer

[t(CO2)]0.23 0.60 0.43 0.31 0.30 1.87 基准线排放量

Emission of baseline

[t(CO2)]199.47 512.95 370.46 270.72 256.48 1610.08 表 5 甘肃省临洮县5个秸秆成型燃料集中供暖试点项目温室气体排放量汇总

Table 5. Summary of project greenhouse gas emissions of five straw briquette central heating pilot projects in Lintao County, Gansu Province

排放源

Source of emission八里铺镇政府办公楼

Government building of Balipu Town新添镇政府办公楼

Government building

of Xintian Town峡口镇政府办公楼

Government building

of Xiakou Town漫湾乡政府办公楼

Government building

of Manwan Town康家集乡政府办公楼

Government building

of Kangjiaji Town合计

Totalt(CO2) 表 6 甘肃省临洮县5个秸秆成型燃料集中供暖试点净温室气体减排量

Table 6. Net greenhouse gas emissions reduction of five straw briquette central heating pilot projects in Lintao County, Gansu Province

排放源

Source of emission八里铺镇政府办公楼

Government building of Balipu Town新添镇政府办公楼

Government building of Xintian Town峡口镇政府办公楼

Government building of Xiakou Town漫湾乡政府办公楼

Government building of Manwan Town康家集乡政府办公楼

Government building of Kangjiaji Town合计

Totalt(CO2) 净减排量

Net emissions reduction187.36 481.23 345.89 251.46 239.47 1505.41 表 7 临洮县秸秆成型燃料集中供暖工程温室气体减排量

Table 7. Greenhouse gas emission reduction of central heating project with straw briquette fuel in Lintao County

情景

Scene排放源

Source of emission排放量

Emission总排放量

Net emissions reductiont(CO2) 基准线

Baseline秸秆自然腐解

Natural decomposition of straw38.45 1610.08 秸秆成型燃料替代化石燃料

Straw briquette fuel replacing fossil fuel1569.76 灰渣替代钾肥

Ash replacing potash fertilizer1.87 项目排放

Project emission运输过程化石燃料消耗

Fossil fuel consumption for transporting10.01 104.67 电力消耗

Electricity consuming63.16 产品利用 (秸秆成型燃料燃烧)

Straw briquette fuel utilization (straw briquette combustion)31.50 泄漏排放

Leakage emission工程泄漏

Project leakage0 0 -

[1] 贾智彬, 孙德强, 张映红, 等. 美国能源战略发展史对中国能源战略发展的启示[J]. 中外能源, 2016, 21(2): 1−7JIA Z B, SUN D Q, ZHANG Y H, et al. What China can learn from the US history of energy strategy development[J]. Sino-Global Energy, 2016, 21(2): 1−7 [2] MCKENDRY P. Energy production from biomass (part 1): overview of biomass[J]. Bioresource Technology, 2002, 83(1): 37−46 doi: 10.1016/S0960-8524(01)00118-3 [3] 石元春. 我国生物质能源发展综述[J]. 智慧电力, 2017, 45(7): 1−5, 42 doi: 10.3969/j.issn.1673-7598.2017.07.001SHI Y C. Overview of biomass energy development in China[J]. Smart Power, 2017, 45(7): 1−5, 42 doi: 10.3969/j.issn.1673-7598.2017.07.001 [4] 田文善, 李赤明. 中国北方地区“生物质+”农村清洁取暖模式[J]. 农业工程技术, 2020, 40(14): 47−48TIAN W S, LI C M. “Biomass +” rural clean heating model in northern China[J]. Agricultural Engineering Technology, 2020, 40(14): 47−48 [5] ZHANG Q L, JI Y Y, JIN L W. Technical economy feasibility analysis of biomass stove heating system[J]. Energy Procedia, 2017, 143: 144−149 doi: 10.1016/j.egypro.2017.12.662 [6] 毕于运, 寇建平, 王道龙. 中国秸秆资源综合利用技术[M]. 北京: 中国农业科学技术出版社, 2008BI Y Y, KOU J P, WANG D L. Comprehensive Utilization Technology of Straw Resources in China[M]. Beijing: China Agricultural Science and Technology Press, 2008 [7] 林成先, 杨尚宝, 陈景文, 等. 煤与秸秆成型燃料的复合生命周期对比评价[J]. 环境科学学报, 2009, 29(11): 2451−2457LIN C X, YANG S B, CHEN J W, et al. Hybrid life cycle analysis for coal versus straw briquettes[J]. Acta Scientiae Circumstantiae, 2009, 29(11): 2451−2457 [8] 张双奇, 邓梦思, 单明, 等. 基于秸秆露天焚烧量的北方农村地区秸秆成型燃料替代采暖散煤节能减排研究[J]. 农业环境科学学报, 2017, 36(12): 2506−2514 doi: 10.11654/jaes.2017-0782ZHANG S Q, DENG M S, SHAN M, et al. Study on the energy and environmental impacts of substituting molded straw fuels for heating coal in rural areas of northern China based on the amount of straw open burning[J]. Journal of Agro-Environment Science, 2017, 36(12): 2506−2514 doi: 10.11654/jaes.2017-0782 [9] 张爱祥, 赵国凌, 毛军, 等. 燃生物质小型锅炉凸显节能减排优势[J]. 中国特种设备安全, 2014, 30(1): 49−53ZHANG A X, ZHAO G L, MAO J, et al. Small biomass fired boilers highlight the advantages of energy conservation and emission reduction[J]. China Special Equipment Safety, 2014, 30(1): 49−53 [10] 赵航. 浅析中小燃煤工业锅炉节能减排途径及情景[J]. 中国设备工程, 2018(21): 68−69 doi: 10.3969/j.issn.1671-0711.2018.21.029ZHAO H. Analysis on energy saving and emission reduction ways and scenarios of small and medium-sized coal-fired industrial boilers[J]. China Plant Engineering, 2018(21): 68−69 doi: 10.3969/j.issn.1671-0711.2018.21.029 [11] 谢小天. 生物质固体成型燃料技术路线生命周期环境影响评价[D]. 青岛: 青岛科技大学, 2016XIE X T. Comparative life cycle assessment of pellet production and utilization with different technical scenarios[D]. Qingdao: Qingdao University of Science & Technology, 2016 [12] KIM S, DALE B E. Global potential bioethanol production from wasted crops and crop residues[J]. Biomass and Bioenergy, 2004, 26(4): 361−375 doi: 10.1016/j.biombioe.2003.08.002 [13] 闫翠萍, 张玉铭, 胡春胜, 等. 不同耕作措施下小麦–玉米轮作农田温室气体交换及其综合增温潜势[J]. 中国生态农业学报, 2016, 24(6): 704−715YAN C P, ZHANG Y M, HU C S, et al. Greenhouse gas exchange and comprehensive global warming potential under different wheat-maize rotation patterns[J]. Chinese Journal of Eco-Agriculture, 2016, 24(6): 704−715 [14] IPCC. Climate Change 2013: The Physical Science Basis. [EB/OL]. GlobalChange, [2021–6–30]. https://www.globalchange.gov/browse/reports/ipcc-climate-change-2013-physical-science-basis [15] 高春雨, 王立刚, 李虎, 等. 区域尺度农田N2O排放量估算研究进展[J]. 中国农业科学, 2011, 44(2): 316−324 doi: 10.3864/j.issn.0578-1752.2011.02.011GAO C Y, WANG L G, LI H, et al. Advances and prospects of N2O emission from cropland at regional scale[J]. Scientia Agricultura Sinica, 2011, 44(2): 316−324 doi: 10.3864/j.issn.0578-1752.2011.02.011 [16] 国家发展和改革委员会应对气候变化司. CM-073-V01 供热锅炉使用生物质废弃物替代化石燃料[EB/OL]. 中国清洁发展机制网. [2021-06-30]. http://cdm.ccchina.org.cn/archiver/cdmcn/UpFile/Files/Default/20140123143321982033.pdfClimate change Department of National Development and Reform Commission. CM-073-V01 heating boiler uses biomass waste instead of fossil fuel [EB/OL]. Clean Development Mechanism Network in China. [2021-06-30]. http://cdm.ccchina.org.cn/archiver/cdmcn/UpFile/Files/Default/20140123143321982033.pdf [17] 冯新新. 秸秆成型燃料集中供暖温室气体减排研究[D]. 北京: 中国农业科学院, 2021FENG X X. Study on greenhouse gas emission reduction of straw briquette fuel for central heating[D]. Beijing: Chinese Academy of Agricultural Sciences, 2021 [18] IPCC. 2006 IPCC Guidelines for national greenhouse gas inventories[EB/OL]. IPCC Web Sites. [2021-06-30]. https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol2.html [19] 刘万秋. 山东省昌邑市主要农作物能源消耗调查与评价[D]. 北京: 中国农业科学院, 2010LIU W Q. Investigation and assessment on major crops’ energy consumption of Changyi City in Shandong[D]. Beijing: Chinese Academy of Agricultural Sciences, 2010 [20] 彭美春, 李嘉如, 胡红斐. 营运货车道路运行油耗及碳排放因子研究[J]. 汽车技术, 2015(4): 37−40 doi: 10.3969/j.issn.1000-3703.2015.04.010PENG M C, LI J R, HU H F. Research on fuel consumption & carbon emission factor of road freight trucks[J]. Automobile Technology, 2015(4): 37−40 doi: 10.3969/j.issn.1000-3703.2015.04.010 [21] 唐伟, 何平, 杨强, 等. 基于IVE模型和大数据分析的杭州市道路移动源主要温室气体排放清单研究[J]. 环境科学学报, 2018, 38(4): 1368−1376TANG W, HE P, YANG Q, et al. Study on greenhouse gas emission inventory of road source in Hangzhou based on IVE model and large data analysis[J]. Acta Scientiae Circumstantiae, 2018, 38(4): 1368−1376 [22] 王莹, 王亚静, 王红彦, 等. 秸秆热解气化工程生态价值量估算方法研究[J]. 中国生态农业学报(中英文), 2020, 28(6): 920−930WANG Y, WANG Y J, WANG H Y, et al. Ecological value estimation method of the straw pyrolysis engineering[J]. Chinese Journal of Eco-Agriculture, 2020, 28(6): 920−930 [23] 库丽霞, 陈彦惠, 岳建芝, 等. 玉米秸秆能量指标的测定和利用研究[J]. 玉米科学, 2004, 12(1): 114−118 doi: 10.3969/j.issn.1005-0906.2004.01.037KU L X, CHEN Y H, YUE J Z, et al. Analysis on energy index of the maize stem and its utilization[J]. Journal of Maize Sciences, 2004, 12(1): 114−118 doi: 10.3969/j.issn.1005-0906.2004.01.037 [24] 刘圣勇, 张百良, 张全国, 等. 玉米秸秆成型燃料锅炉的设计与试验研究[J]. 热科学与技术, 2003, 2(2): 173−177 doi: 10.3969/j.issn.1671-8097.2003.02.016LIU S Y, ZHANG B L, ZHANG Q G, et al. Design and study of cornstalk briquette boiler[J]. Journal of Thermal Science and Technology, 2003, 2(2): 173−177 doi: 10.3969/j.issn.1671-8097.2003.02.016 [25] 帖青敏. 秸秆成型燃料燃烧动力学分析及燃烧过程数值模拟[D]. 天津: 河北工业大学, 2012TIE Q M. Straw briquette combustion dynamics analysis and numerical simulation on combustion process[D]. Tianjin: Hebei University of Technology, 2012 [26] 梁星星, 张永旺, 王斌, 等. 生物质电厂废弃物草木灰成分分析及成形[J]. 化工进展, 2020, 39(6): 2487−2494LIANG X X, ZHANG Y W, WANG B, et al. Component analysis and forming of waste-plant ash from biomass power plant[J]. Chemical Industry and Engineering Progress, 2020, 39(6): 2487−2494 [27] 张润锴. 生物质秸秆收储运与成型燃料生产及供热运营模式研究[D]. 郑州: 河南农业大学, 2019ZHANG R K. Study on biomass straw storage and transportation, molding fuel production and heating operation mode[D]. Zhengzhou: Henan Agricultural University, 2019 [28] 周建强, 高攀, 董长青, 等. 生物质锅炉脱硝技术及工程应用[J]. 热力发电, 2018, 47(10): 1−5ZHOU J Q, GAO P, DONG C Q, et al. Denitrification technology of biomass boilers and its engineering application[J]. Thermal Power Generation, 2018, 47(10): 1−5 [29] 毛洪钧, 李悦宁, 林应超, 等. 生物质锅炉氮氧化物排放控制技术研究进展[J]. 工程科学学报, 2019, 41(1): 1−11MAO H J, LI Y N, LIN Y C, et al. Overview of advances in emission control technologies for nitric oxides from biomass boilers[J]. Chinese Journal of Engineering, 2019, 41(1): 1−11 [30] 王献民. 生物质锅炉脱硝技术发展现状分析[J]. 节能与环保, 2020(5): 54−55 doi: 10.3969/j.issn.1009-539X.2020.05.025WANG X M. Analysis on the development of denitration technology of biomass boiler[J]. Energy Saving and Environmental Protection, 2020(5): 54−55 doi: 10.3969/j.issn.1009-539X.2020.05.025 [31] 喻兵. 生物质锅炉尾气超低排放技术[J]. 价值工程, 2019, 38(10): 105−108YU B. Biomass boiler exhaust ultra-low emission technology[J]. Value Engineering, 2019, 38(10): 105−108 [32] 薛玉宝, 郜光伟, 武新虎, 等. 生物质直燃锅炉超低排放脱硝技术研究[J]. 河北电力技术, 2020, 39(2): 29−32 doi: 10.3969/j.issn.1001-9898.2020.02.007XUE Y B, GAO G W, WU X H, et al. Research on ultra-low emissions denitrification technology for biomass direct-fired boiler[J]. Hebei Electric Power, 2020, 39(2): 29−32 doi: 10.3969/j.issn.1001-9898.2020.02.007 [33] 高劲豪, 张幼安, 高原. 生物质锅炉烟气脱硫脱硝技术方案选择[J]. 硫酸工业, 2017(8): 52−54, 58 doi: 10.3969/j.issn.1002-1507.2017.08.013GAO J H, ZHANG Y A, GAO Y. Choice of technical options about biomass boiler flue gas desulphurization and denitrification[J]. Sulphuric Acid Industry, 2017(8): 52−54, 58 doi: 10.3969/j.issn.1002-1507.2017.08.013 [34] 史俊高, 安晓熙, 房有为. 生物质锅炉脱硝技术现状及研究进展[J]. 化学工业, 2019, 37(3): 52−58 doi: 10.3969/j.issn.1673-9647.2019.03.009SHI J G, AN X X, FANG Y W. Status and research progress of denitrification technology in biomass boilers[J]. Chemical Industry, 2019, 37(3): 52−58 doi: 10.3969/j.issn.1673-9647.2019.03.009 -

下载:

下载: