Accelerating carbon conversion in garden waste composting with food waste-expanding microbial inoculants

-

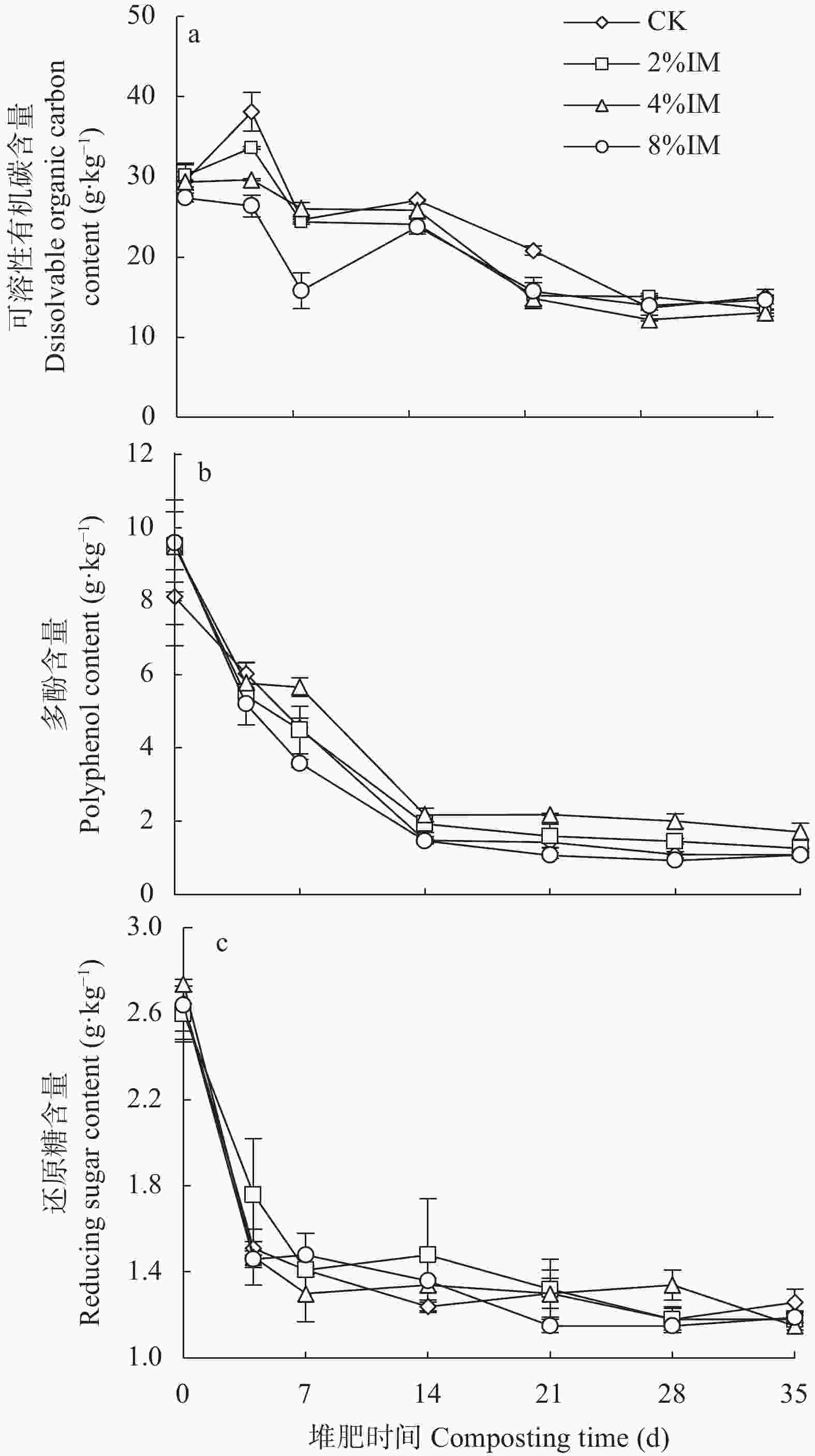

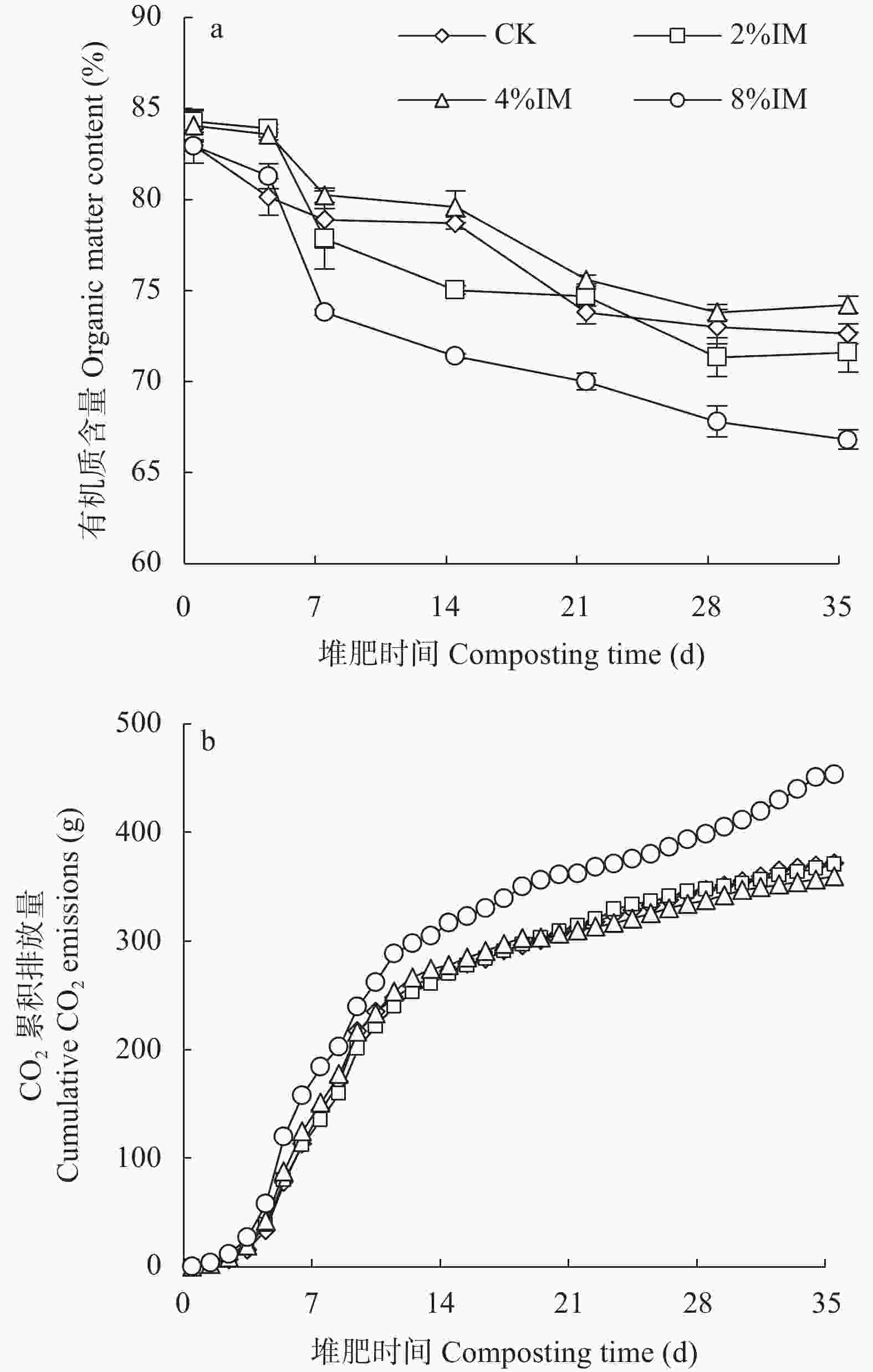

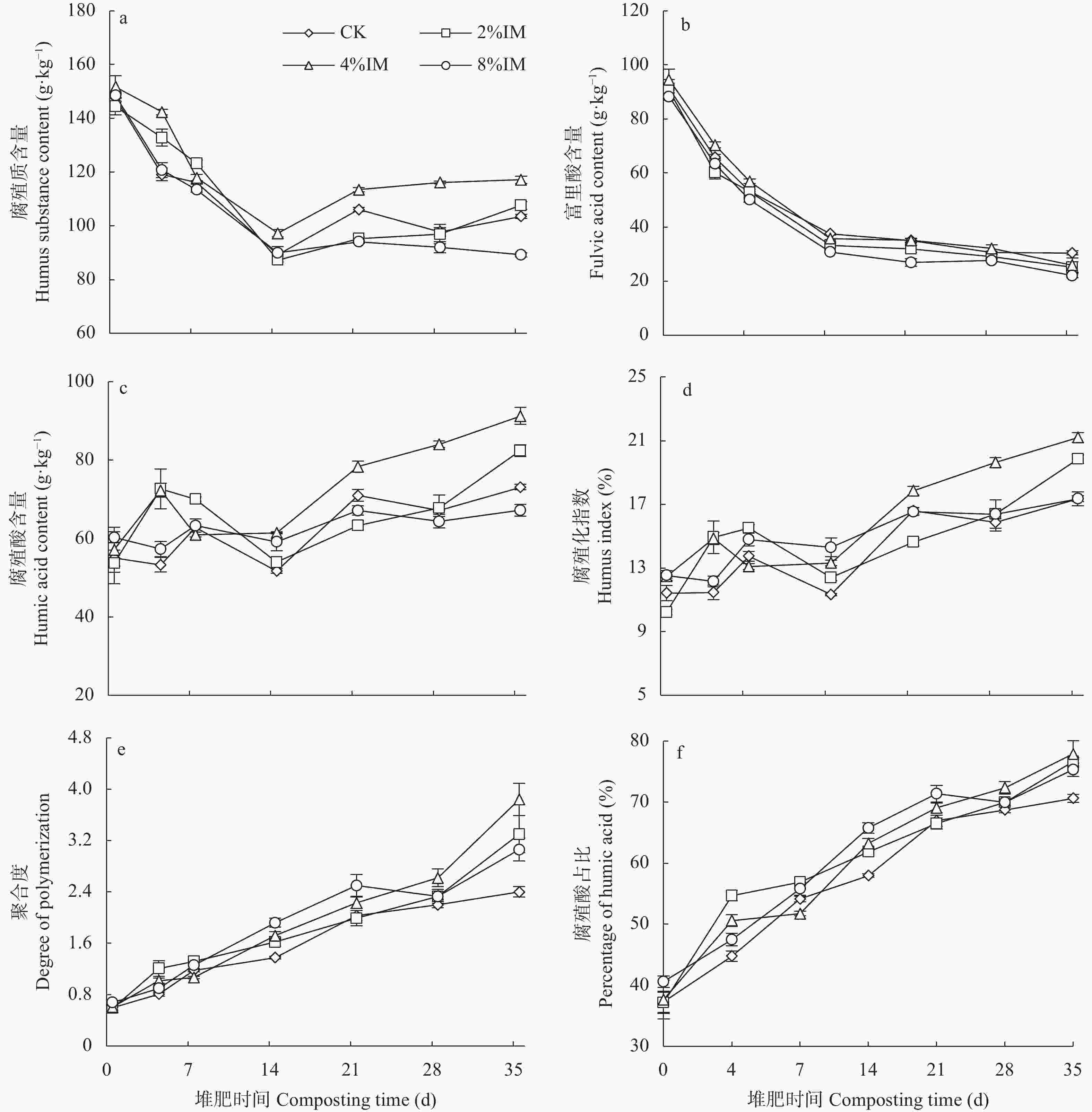

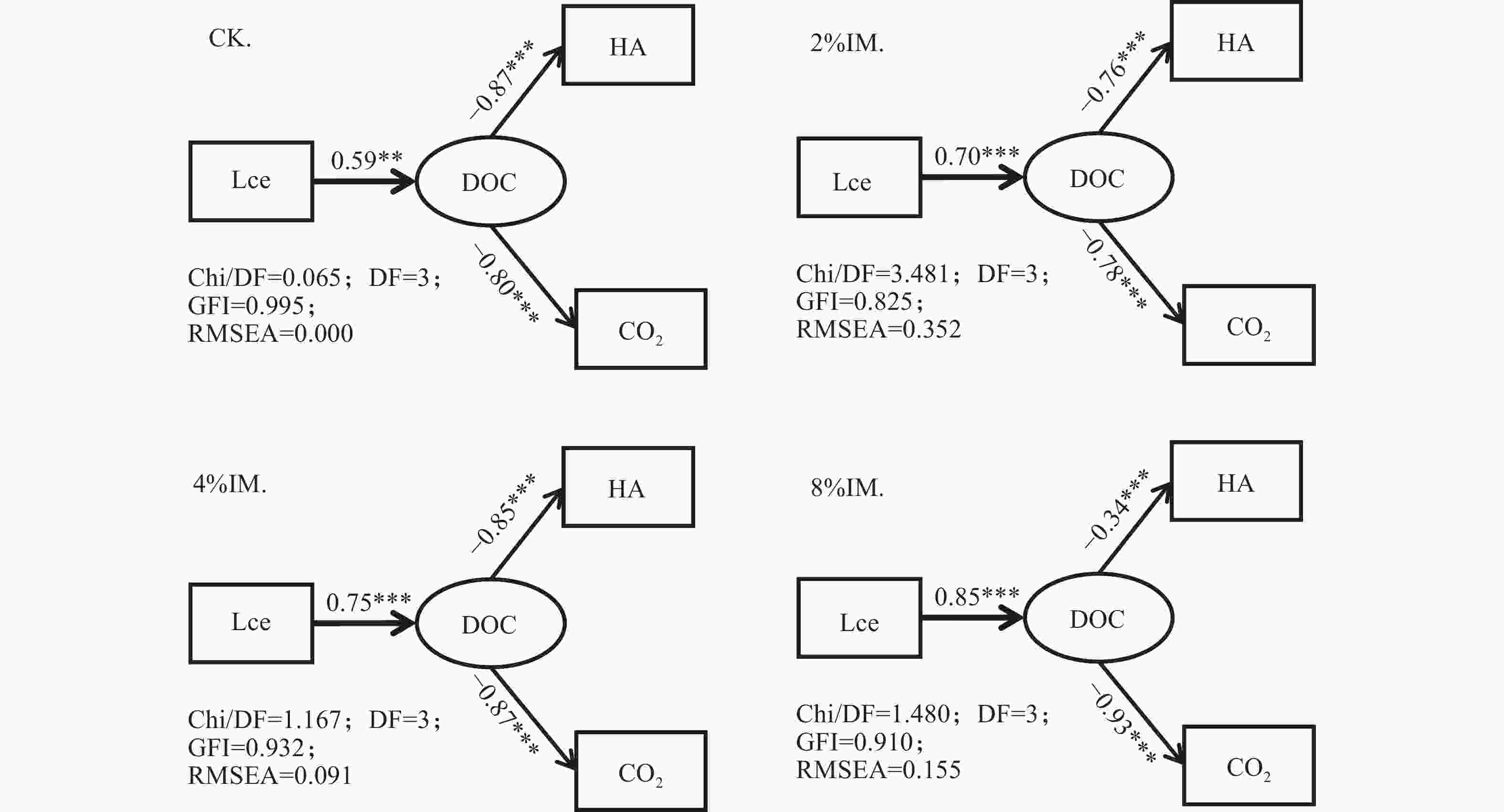

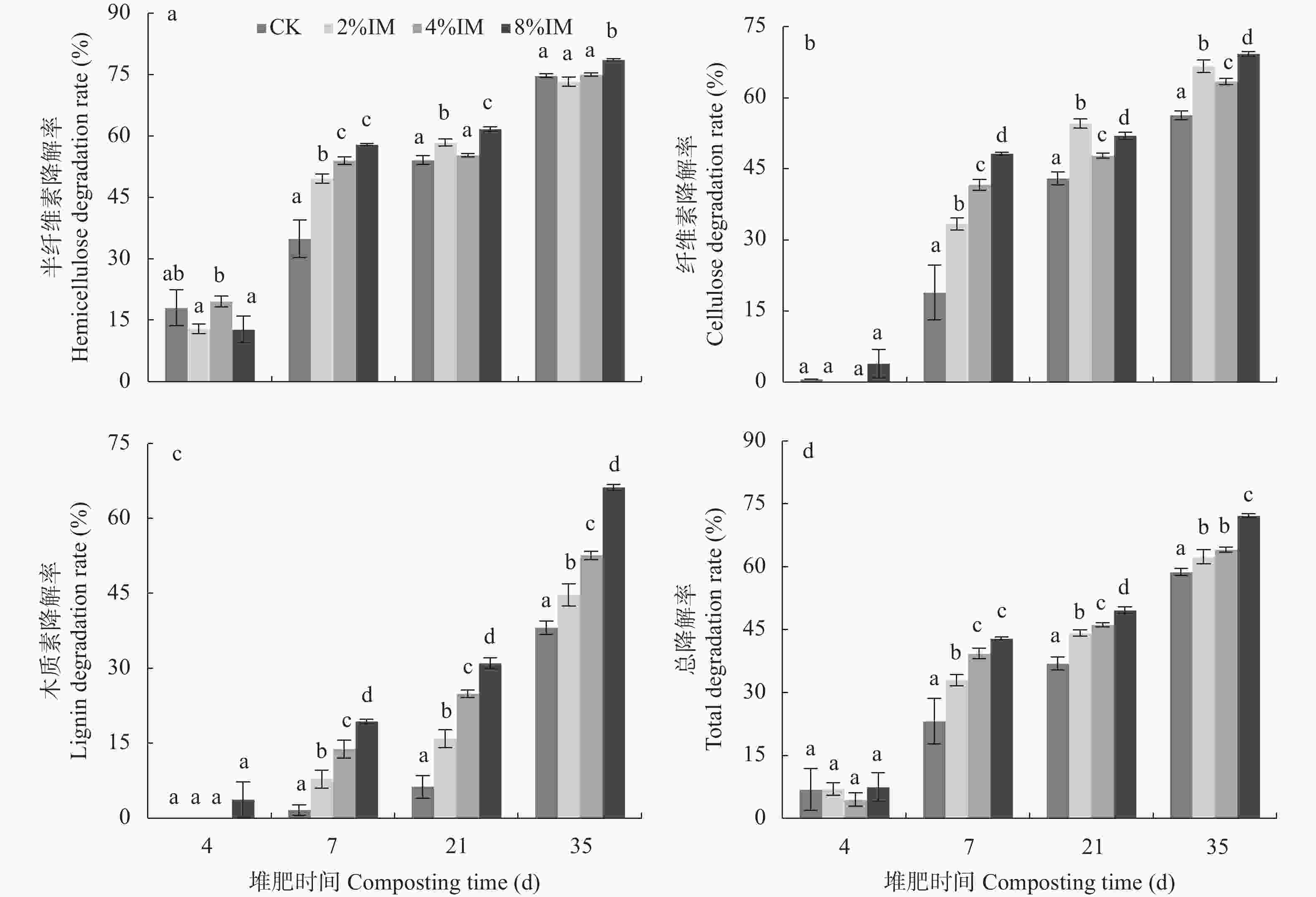

摘要: 高木质纤维素含量制约了园林废弃物的堆肥化应用, 添加外源菌剂是加快木质纤维素降解的有效手段。为降低菌剂生产成本并提高接种效率, 本研究利用食品残渣(苹果渣、豆渣)代替常规碳氮源(葡萄糖、蛋白胨)进行木质纤维素降解菌的扩繁, 扩繁产品活菌数高达3.7×1010 cfu∙mL−1, 相较工业培养基增加了46.2%。探讨了不同降解菌接种量(0、2%、4%、8%, 干重计)对园林废弃物堆肥过程碳素转化的影响。结果表明, 接种处理显著增加了木质纤维素的降解(P<0.05), 2%、4%、8%接种处理(2%、4%、8%IM)的总木质纤维素降解率较CK分别提高6.3%、9.2%、23.0%, 其中8%IM处理加速了碳素的完全矿化, 导致腐殖质前体物(多酚、还原糖)被完全降解生成了CO2, 抑制了腐殖化的进行, 而4%IM处理在加快木质纤维素降解的同时促进了腐殖酸(HA)的合成, 其最终HA含量达到91.3g/kg, 较CK、2%IM、8%IM处理分别提高了24.9、10.7、35.8%。因此, 以食品残渣为培养基质可完全实现木质纤维素降解菌的生长扩繁, 同时, 4%接种量更有利于园林废弃物堆肥腐殖化的进行和碳素的保存, 本研究为多源废弃物高效协同处理提供理论依据。Abstract: The expansion of urbanization has resulted in the generation of a large amount of garden waste (0.4 million tons), while traditional treatment methods (incineration, landfill) tend to cause serious environmental pollution and waste of resources. Composting is an effective way to realize the resource utilization of garden waste. However, the high lignocellulose content restricts the resource utilization of garden waste. Accelerating the degradation of lignocellulose in the composting process is of great significance to achieve effective resource utilisation of garden waste. Inoculation with exogenous microorganisms is considered an environmentally friendly and cost-effective way to accelerate lignocellulose degradation. In order to further reduce the cost of inoculum production and improve the inoculation efficiency. In this study, food residues (apple dregs, bean dregs) were used instead of conventional carbon and nitrogen sources (glucose, peptone) to propagate lignocellulose-degrading bacteria, and the number of viable bacteria in the multiplication product reached 3.7×1010 cfu∙ml−1, which increased by 46.2% compared with the traditional industrial medium. The effects of different inoculum amounts (0, 2%, 4% and 8%, dry weight) on carbon conversion during garden waste composting were also discussed. The results showed that the inoculation treatment significantly increased the degradation of lignocellulose (P<0.05). The total lignocellulose degradation rates of the 2%, 4%, and 8% inoculation treatments (2%, 4%, and 8% IM) were increased by 6.3, 9.2, and 23.0%, respectively, compared with CK. The dynamic changes of humus precursors (reducing sugars andpolyphenols) and humus components were further analyzed. The 8%IM treatment accelerated the complete mineralization of carbon, resulting in the complete degradation of humus precursors (polyphenols, reducing sugars) into CO2, which inhibited the humification. Compared to CK, 2%IM and 4%IM, the cumulative CO2 emissions of 8%IM increased by 21.9%, 22.3% and 26.0% respectively. The 4% IM treatment accelerated the degradation of lignocellulose while promoting the synthesis of humic acid (HA). The final HA content reached 91.3g∙kg−1, which was 24.9, 10.7, and 35.8% higher than that of CK, 2%IM, and 8%IM treatments, respectively. These results indicate that appropriate inoculation is beneficial to the directional transformation of lignocellulose to humic acid, whereas excessive inoculation would lead to an excessive loss of organic matter due to the high metabolic activity of microorganisms, and the degradation efficiency of lignocellulose is lower when inoculated with a small amount.This view was further proved by partial least square path analysis model in this study. The conversion of lignocellulose to DOC increased with the increase of inoculation amount (R of CK, 2%IM, 4%IM and 8%IM were 0.59, 0.70, 0.75 and 0.85, respectively), while the R value of 4%IM from DOC to HA was −0.85, which was higher than 2%IM (−0.76) and 8%IM (−0.34). Therefore, the growth and propagation of lignocellulose-degrading bacteria can be completely realized by using food residues as culture substrate. Meanwhile, 4% inoculation amount is more conducive to the humification of garden waste compost and the preservation of carbon. This study provides reference for garden waste composting inoculation process and theoretical basis for multi-source waste efficient collaborative treatment.

-

Key words:

- Composting /

- Garden waste /

- Carbon transformation /

- Inoculant /

- Lignocellulose degradation /

- Humification

-

图 1 接种量对堆肥过程木质纤维素降解的影响

CK: 对照处理; 2%IM: 添加2%菌剂处理; 4%IM: 添加4%菌剂处理; 8%IM: 添加8%菌剂处理; 不同小写字母表示不同处理间存在显著性差异(P<0.05)。CK: control; 2%IM: treatment with 2% inoculum; 4%IM: treatment with 4% inoculum; 8%IM: treatment with 8% inoculum. Different lowercase letters indicate significant differences between different treatments (P<0.05)

Figure 1. Effects of inoculum size on lignocellulose degradation during composting

图 5 接种量对堆肥碳素转化途径的影响

DOC: 可溶性有机碳; Lce: 木质纤维素; HA: 腐殖酸; CK: 对照处理; 2%IM: 添加2%菌剂处理; 4%IM: 添加4%菌剂处理; 8%IM: 添加8%菌剂处理。DOC: Dissolved organic carbon; Lce: Lignocellulose; HA: Humic acid; CK: control; 2% IM: treatment with 2% inoculum; 4% IM: treatment with 4% inoculum; 8% IM: treatment with 8% inoculum.

Figure 5. Effects of inoculum size on carbon conversion pathway during composting

表 1 试验材料的理化性状(n=3)

Table 1. Physical and chemical properties of experimental materials (n=3)

试验材料

Materials含水率

Moisture

content/%有机质a

Organic

matter/%总氮a

Total

nitrogen/%碳氮比a

C/NpH值

pH value电导率

Electrical

conductivity/(mS·cm−1)总糖a

Total sugar

content/%园林废弃物

Garden waste11.00±0.34 84.74±0.56 1.49±0.00 34.14±0.20 7.32±0.02 1.55±0.17 — 餐厨垃圾

Food waste78.55±2.23 91.74±0.11 2.89±0.02 14.61±0.32 4.58±0.07 3.30±0.20 — 苹果渣

Apple pomace82.81±0.58 98.04±0.14 0.81±0.02 69.87±1.82 5.67±0.09 — 20.75±0.58 豆渣

Bean dregs79.95±4.14 95.73±0.07 2.64±0.01 21.02±0.09 7.07±0.04 — 37.29±1.29 “a”: 基于物料干重; “—”: 表示未检测。“a”: based on dry weight of material; “—”: not measured. 表 2 食品残渣(苹果渣、豆渣)代替常规碳、氮源 (培养Ⅱ)对培养72 h后菌液活菌数与酶活性的影响

Table 2. Effect of food residues (apple pomace, soybean pomace) instead of conventional carbon and nitrogen sources on the viability and enzymatic activity of the broth after 72 h incubation

处理

Treatment活菌数

Viable count

(1010 cfu∙mL−1)木聚糖酶

Xylanase

(U∙mL−1)纤维素酶

Cellulase

(U∙mL−1)漆酶

Laccase

(U∙mL−1)锰过氧化物酶

Manganese peroxidase

(U∙mL−1)木质素过氧化物酶

Lignin peroxidase

(U∙mL−1)培养基 I Medium I 2.53±0.41a 337.40±108.81a 73.82±9.55a 3.71±0.69a 11.26±3.97a 2.98±1.67a 培养基 II Medium II 3.70±0.37b 597.40±171.21b 99.47±5.99b 4.91±2.22a 22.38±2.46b 12.39±1.67b 不同小写字母表示不同处理间存在显著性差异(P<0.05)。Different lowercase letters indicate significant differences between different treatments (P<0.05). -

[1] 刘瑜, 戚智勇, 赵佳颖, 等. 我国城市园林废弃物及其资源化利用现状[J]. 再生资源与循环经济, 2020, 13(8): 38−44 doi: 10.3969/j.issn.1674-0912.2020.08.009LIU Y, QI Z Y, ZHAO J Y, et al. Urban garden waste and its resource utilization in China[J]. Recyclable Resources and Circular Economy, 2020, 13(8): 38−44 doi: 10.3969/j.issn.1674-0912.2020.08.009 [2] GABHANE J, WILLIAM S P, BIDYADHAR R, et al. Additives aided composting of green waste: effects on organic matter degradation, compost maturity, and quality of the finished compost[J]. Bioresource Technology, 2012, 114: 382−388 doi: 10.1016/j.biortech.2012.02.040 [3] HUANG G F, WU Q T, WONG J W C, et al. Transformation of organic matter during co-composting of pig manure with sawdust[J]. Bioresource Technology, 2006, 97(15): 1834−1842 doi: 10.1016/j.biortech.2005.08.024 [4] CHEN M L, HUANG Y M, LIU H J, et al. Impact of different nitrogen source on the compost quality and greenhouse gas emissions during composting of garden waste[J]. Process Safety and Environmental Protection, 2019, 124: 326−335 doi: 10.1016/j.psep.2019.03.006 [5] 薛晶晶, 李彦明, 常瑞雪, 等. 厨余与园林废物共堆肥过程氮素转化及损失[J]. 农业工程学报, 2021, 37(10): 192−197 doi: 10.11975/j.issn.1002-6819.2021.10.023XUE J J, LI Y M, CHANG R X, et al. Nitrogen transformation and loss during co-composting of kitchen and garden wastes[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(10): 192−197 doi: 10.11975/j.issn.1002-6819.2021.10.023 [6] ZHANG L, SUN X Y. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste[J]. Waste Management, 2016, 48: 115−126 doi: 10.1016/j.wasman.2015.11.032 [7] WU D, WEI Z M, ZHAO Y, et al. Improved lignocellulose degradation efficiency based on Fenton pretreatment during rice straw composting[J]. Bioresource Technology, 2019, 294: 122132 doi: 10.1016/j.biortech.2019.122132 [8] NAKHSHINIEV B, BIDDINIKA M K, GONZALES H B, et al. Evaluation of hydrothermal treatment in enhancing rice straw compost stability and maturity[J]. Bioresource Technology, 2014, 151: 306−313 doi: 10.1016/j.biortech.2013.10.083 [9] WEI Y Q, WU D, WEI D, et al. Improved lignocellulose-degrading performance during straw composting from diverse sources with actinomycetes inoculation by regulating the key enzyme activities[J]. Bioresource Technology, 2019, 271: 66−74 doi: 10.1016/j.biortech.2018.09.081 [10] HARINDINTWALI J D, ZHOU J L, YU X B. Lignocellulosic crop residue composting by cellulolytic nitrogen-fixing bacteria: a novel tool for environmental sustainability[J]. Science of the Total Environment, 2020, 715: 136912 doi: 10.1016/j.scitotenv.2020.136912 [11] WANG C, DONG D, WANG H S, et al. Metagenomic analysis of microbial consortia enriched from compost: new insights into the role of Actinobacteria in lignocellulose decomposition[J]. Biotechnology for Biofuels, 2016, 9: 22 doi: 10.1186/s13068-016-0440-2 [12] WU J Q, ZHAO Y, ZHAO W, et al. Effect of precursors combined with bacteria communities on the formation of humic substances during different materials composting[J]. Bioresource Technology, 2017, 226: 191−199 doi: 10.1016/j.biortech.2016.12.031 [13] ZHANG Z C, ZHAO Y, YANG T X, et al. Effects of exogenous protein-like precursors on humification process during lignocellulose-like biomass composting: Amino acids as the key linker to promote humification process[J]. Bioresource Technology, 2019, 291: 121882 doi: 10.1016/j.biortech.2019.121882 [14] ZHAO Y, ZHAO Y, ZHANG Z C, et al. Effect of thermo-tolerant actinomycetes inoculation on cellulose degradation and the formation of humic substances during composting[J]. Waste Management, 2017, 68: 64−73 doi: 10.1016/j.wasman.2017.06.022 [15] 曹玉博, 张陆, 王选, 等. 畜禽废弃物堆肥氨气与温室气体协同减排研究[J]. 农业环境科学学报, 2020, 39(4): 923−932 doi: 10.11654/jaes.2020-0104CAO Y B, ZHANG L, WANG X, et al. Synergistic mitigation of ammonia and greenhouse gas emissions during livestock waste composting[J]. Journal of Agro-Environment Science, 2020, 39(4): 923−932 doi: 10.11654/jaes.2020-0104 [16] 赵彬涵, 孙宪昀, 黄俊, 等. 微生物在有机固废堆肥中的作用与应用[J]. 微生物学通报, 2021, 48(1): 223−240 doi: 10.13344/j.microbiol.china.200506ZHAO B H, SUN X Y, HUANG J, et al. Application and effects of microbial additives in aerobic composting of organic solid wastes: a review[J]. Microbiology China, 2021, 48(1): 223−240 doi: 10.13344/j.microbiol.china.200506 [17] WANG X, BAI Z H, YAO Y, et al. Composting with negative pressure aeration for the mitigation of ammonia emissions and global warming potential[J]. Journal of Cleaner Production, 2018, 195: 448−457 doi: 10.1016/j.jclepro.2018.05.146 [18] 田微微. 平板菌落计数法对食品微生物检验的作用研究[J]. 质量安全与检验检测, 2021, 31(4): 75−76TIAN W W. Study on the effect of plate colony counting method on microbial testing of food hygiene[J]. Quality Safety Inspection and Testing, 2021, 31(4): 75−76 [19] 姜兴林. 纤维素酶—木聚糖酶—漆酶的酶学性质及共固定化研究[D]. 长春: 吉林农业大学, 2016JIANG X L. Study on enzymatic characteristic and co-immobilization of cellulase xylanase and laccase[D]. Changchun: Jilin Agricultural University, 2016 [20] 田林双. 木质素降解相关酶类测定标准方法研究[J]. 畜牧与饲料科学, 2009, 30(10): 13−15 doi: 10.3969/j.issn.1672-5190.2009.10.005TIAN L S. Research on standard method for determining ligninolytic enzyme activity[J]. Animal Husbandry and Feed Science, 2009, 30(10): 13−15 doi: 10.3969/j.issn.1672-5190.2009.10.005 [21] CAO Y, CHANG Z Z, WANG J D, et al. The fate of antagonistic microorganisms and antimicrobial substances during anaerobic digestion of pig and dairy manure[J]. Bioresource Technology, 2013, 136: 664−671 doi: 10.1016/j.biortech.2013.01.052 [22] BADDI G A, CEGARRA J, MERLINA G, et al. Qualitative and quantitative evolution of polyphenolic compounds during composting of an olive-mill waste-wheat straw mixture[J]. Journal of Hazardous Materials, 2009, 165(1/2/3): 1119−1123 [23] VAN SOEST P J, ROBERTSON J B, LEWIS B A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition[J]. Journal of Dairy Science, 1991, 74(10): 3583−3597 doi: 10.3168/jds.S0022-0302(91)78551-2 [24] BERNAL M P, ALBURQUERQUE J A, MORAL R. Composting of animal manures and chemical criteria for compost maturity assessment. A review[J]. Bioresource Technology, 2009, 100(22): 5444−5453 doi: 10.1016/j.biortech.2008.11.027 [25] 阎晓莉, 杨中平, 朱新华. 苹果渣的开发利用途径[J]. 农机化研究, 2002, 24(4): 175−177 doi: 10.3969/j.issn.1003-188X.2002.04.071YAN X L, YANG Z P, ZHU X H. The utilize approaches of apple residue[J]. Journal of Agricultural Mechanization Research, 2002, 24(4): 175−177 doi: 10.3969/j.issn.1003-188X.2002.04.071 [26] 姜慧燕, 邹礼根, 翁丽萍, 等. 豆渣营养成分分析及蛋白质营养价值评价[J]. 食品工业, 2020, 41(6): 325−328JIANG H Y, ZOU L G, WENG L P, et al. Nutritional components analyzation and protein nutrition evaluation of soybean residue[J]. The Food Industry, 2020, 41(6): 325−328 [27] WU D, WEI Z M, MOHAMED T A, et al. Lignocellulose biomass bioconversion during composting: mechanism of action of lignocellulase, pretreatment methods and future perspectives[J]. Chemosphere, 2022, 286(Pt 1): 131635 [28] 王晓芳, 徐旭士, 吴敏, 杨亚南. 不同碳源对两株真菌纤维素酶合成的诱导和调控[J]. 应用与环境生物学报, 2002, 8(6): 653−657 doi: 10.3321/j.issn:1006-687X.2002.06.019WANG X F, XU X S, WU M, et al. Induction and regulation of cellulase formation in two trains of fungi by different carbon sources[J]. Chinese Journal of Applied and Environmental Biology, 2002, 8(6): 653−657 doi: 10.3321/j.issn:1006-687X.2002.06.019 [29] 于俊杰, 赫荣琳, 武改红, 等. 复合木质纤维素酶菌株筛选及其培养条件优化[J]. 生物技术通报, 2013(4): 101−109 doi: 10.13560/j.cnki.biotech.bull.1985.2013.04.010YU J J, HE R L, WU G H, et al. Isolation of strain producing complex lignocellulase and the optimization of culture conditions[J]. Biotechnology Bulletin, 2013(4): 101−109 doi: 10.13560/j.cnki.biotech.bull.1985.2013.04.010 [30] 毕杨, 张志才. 青霉菌液体发酵合成木质素过氧化物酶条件优化[J]. 饲料研究, 2017(16): 36−41 doi: 10.13557/j.cnki.issn1002-2813.2017.16.008BI Y, ZHANG Z C. Optimization of lignin peroxidase synthesis by penicillium liquid fermentation[J]. Feed Research, 2017(16): 36−41 doi: 10.13557/j.cnki.issn1002-2813.2017.16.008 [31] ZHU N, ZHU Y Y, LI B Q, et al. Increased enzyme activities and fungal degraders by Gloeophyllum trabeum inoculation improve lignocellulose degradation efficiency during manure-straw composting[J]. Bioresource Technology, 2021, 337: 125427 doi: 10.1016/j.biortech.2021.125427 [32] STRAATHOF A L, COMANS R N J. Input materials and processing conditions control compost dissolved organic carbon quality[J]. Bioresource Technology, 2015, 179: 619−623 doi: 10.1016/j.biortech.2014.12.054 [33] DUAN M L, ZHANG Y H, ZHOU B B, et al. Effects of Bacillus subtilis on carbon components and microbial functional metabolism during cow manure-straw composting[J]. Bioresource Technology, 2020, 303: 122868 doi: 10.1016/j.biortech.2020.122868 [34] WU J Q, ZHAO Y, WANG F, et al. Identifying the action ways of function materials in catalyzing organic waste transformation into humus during chicken manure composting[J]. Bioresource Technology, 2020, 303: 122927 doi: 10.1016/j.biortech.2020.122927 [35] CHANG R X, GUO Q Y, CHEN Q, et al. Effect of initial material bulk density and easily-degraded organic matter content on temperature changes during composting of cucumber stalk[J]. Journal of Environmental Sciences, 2019, 80: 306−315 doi: 10.1016/j.jes.2017.10.004 [36] ZHANG S, WEI Z M, ZHAO M Y, et al. Influence of malonic acid and manganese dioxide on humic substance formation and inhibition of CO2 release during composting[J]. Bioresource Technology, 2020, 318: 124075 doi: 10.1016/j.biortech.2020.124075 [37] GAO X T, TAN W B, ZHAO Y, et al. Diversity in the mechanisms of humin formation during composting with different materials[J]. Environmental Science & Technology, 2019, 53(7): 3653−3662 [38] WEI Z M, AHMED MOHAMED T, ZHAO L, et al. Microhabitat drive microbial anabolism to promote carbon sequestration during composting[J]. Bioresource Technology, 2022, 346: 126577 doi: 10.1016/j.biortech.2021.126577 [39] SERRAMIÁ N, SÁNCHEZ-MONEDERO M A, FERNÁNDEZ-HERNÁNDEZ A, et al. Contribution of the lignocellulosic fraction of two-phase olive-mill wastes to the degradation and humification of the organic matter during composting[J]. Waste Management, 2010, 30(10): 1939−1947 doi: 10.1016/j.wasman.2010.04.031 [40] BOONYUEN N, MANOCH L, LUANGSA-ARD J J, et al. Decomposition of sugarcane bagasse with lignocellulose-derived thermotolerant and thermoresistant penicillia and aspergilli[J]. International Biodeterioration & Biodegradation, 2014, 92: 86−100 [41] TIAN X P, YANG T, HE J Z, et al. Fungal community and cellulose-degrading genes in the composting process of Chinese medicinal herbal residues[J]. Bioresource Technology, 2017, 241: 374−383 doi: 10.1016/j.biortech.2017.05.116 [42] HU T, WANG X J, ZHEN L S, et al. Effects of inoculating with lignocellulose-degrading consortium on cellulose-degrading genes and fungal community during co-composting of spent mushroom substrate with swine manure[J]. Bioresource Technology, 2019, 291: 121876 doi: 10.1016/j.biortech.2019.121876 [43] 张陆, 曹玉博, 王惟帅, 等. 鸡粪添加对蔬菜废弃物堆肥腐殖化过程的影响[J]. 中国生态农业学报(中英文), 2022, 30(2): 258−267 doi: 10.12357/cjea.20210536ZHANG L, CAO Y B, WANG W S, et al. Effect of chicken manure addition on humification of vegetable waste in composting process[J]. Chinese Journal of Eco-Agriculture, 2022, 30(2): 258−267 doi: 10.12357/cjea.20210536 [44] 劳德坤, 张陇利, 李永斌, 等. 不同接种量的微生物秸秆腐熟剂对蔬菜副产物堆肥效果的影响[J]. 环境工程学报, 2015, 9(6): 2979−2985 doi: 10.12030/j.cjee.20150672LAO D K, ZHANG L L, LI Y B, et al. Effect of different inoculation amounts of microbial straw decomposition agents on vegetable byproducts composting[J]. Chinese Journal of Environmental Engineering, 2015, 9(6): 2979−2985 doi: 10.12030/j.cjee.20150672 -

下载:

下载: